Description

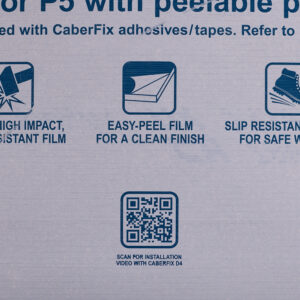

18mm P5 Tongue and Grooved Chipboard, commonly known as P5, is a structural grade flooring board highly regarded by builders because of its moisture-resistant properties. 18mm Caberfloor flooring chipboard typically utilised in flooring applications. The use of this board in the constructions adds strength when the panels are systematically slotted together and then screwed down to the floor’s joists.

18mm Caberfloor chipboard is utilised in almost all general flooring applications, including bathrooms and kitchens. It is ideal for most domestic applications, and thanks to its sanded smooth surface, it can be used in all kinds of floor coverings. Besides, due to its density, it enhances insulation, mainly when used with the correct thermal slab or acoustic type insulation. P5 chipboard flooring sheets are also narrow and effortless to work with, especially in tight spaces like lofts.

Key Features of 18mm P5 Caberfloor Tongue And Groove Chipboard

The following features make 18mm T&G flooring sheets quite desirable:

- P5 chipboard is made from recycled woodchips and therefore minimises the need for landfill disposal.

- It explicitly manufactured in compliance with EN 312-P5 standards.

- High-density structural chipboard.

- Moisture resistant chipboard flooring.

- T&G chipboard flooring groove for fast and effortless installation and enhanced strength.

- 18mm Caberfloor chipboard thickness allows for use with joists, with 400m spacing.

- It adheres to all set environmental and production standards for unswerving quality.

- P5 chipboards have a CE mark implying compliance with EN13986 construction standards.

- It can be applied on most coverings due to its smooth surface.

- It is easy to decorate or use veneer.

- The thin profile and hence easy to cut.

- T&G profile edges.

Advantages of p5 T&G chipboard flooring

- Easy to work

- Affordable

- It can be recycled, and therefore it is environmentally friendly

- Installation can be done even in light rain conditions

- Its surface is anti-slippery, and that offers additional food holding even in wet conditions

- Polymer polish provides an extra moisture barrier

- During construction, it can be exposed to extreme weather and remains unaffected.