MDF

Medium-density fibreboards are the most reliably machinable and paint-ready product for interior joinery and commercial fit-out.

Crafted from wood fibres, resin, and wax pressed under heat, MDF is uniformly dense, consistently finished, and easy to fabricate, a valuable quality for builders, carpenters, and fit-out crews.

What is MDF?

The initials stand for Medium Density Fibreboard. It is an engineered wood sheet product that consists of refined wood fibres that are mixed with wax and resin and pressed under immense pressure and temperature to form flat panels. It is used in various applications such as building material and production of furniture.

Often, many people confuse MDF board with plywood, but MDF wood is effortless to use with industrial machinery and comes with a smooth surface, and that’s why it is suitable for applying surface paint and finishes.

Generally, it is an excellent sheet material; cost-effective, robust and versatile. We often interact with it at work (shop fittings, construction products, furniture), or home (shelving, kitchens, bathrooms, etc.).

Types of MDF Board

Standard MDF

Standard MDF is the way to go for structural interior applications where moisture exposure is minimal. With a density hovering around 700 to 750 kg/m³, it is easy to machine for precise work in shelving, carcasses, skirtings, and internal framing.

The smooth and knot-free face is perfect for priming and painting. Just ensure to seal the edges, which remain absorbent.

Moisture-Resistant MDF (MR MDF)

In humid places, such as kitchens, bathrooms, or utility rooms, MR MDF upgrades the standard version. It has moisture-repellent resin, which gives it a greenish tinge, reducing swelling in damp conditions.

However, it is not waterproof and has to be sealed on cut edges. Machining, strength, and finish characteristics match standard MDF, with a slight premium.

Fire-Retardant MDF (FR MDF)

In public, institutional, or commercial buildings where fire codes apply, FR MDF is engineered to slow flame spread. It is treated with chemical additives and usually has a red or pink core for quick identification.

It cuts and finishes like standard MDF, though it will need flame retardant paint to maintain the rating over time, and is perfect for doors, partitions, ceilings, and walls.

Melamine-Faced MDF

When you need furniture-grade boards off the shelf, melamine-faced MDF is the answer. It is already finished with a melamine surface, often woodgrain or white, and does not require painting.

It is rigid, ready to install, and works nicely in office, wardrobes, kitchen carcasses, and more. The edge requires some sanding to retain the clean appearance when cut.

Veneered MDF

To get that solid wood feel and look without sacrificing stability, check out veneered MDF. It looks like a real-wood veneer, such as oak or walnut, over a standard MDF core. This provides superior surface quality for premium furniture, counters, doors, and other aesthetic applications.

After fabrication, the surface can be oiled or lacquered just like solid timber for added longevity.

Flexible (Bendy) MDF

The uniqueness of curved joinery is yours if you know about flexible MDF, sometimes called bendy or grooved-back MDF. Grooves, cut at the factory, allow the board to bend along one axis without creasing.

After shaping and finishing, the grooves are covered up with paint or facing. This type of MDF is widely seen in curved panels, arches, contoured furniture pieces, and so on.

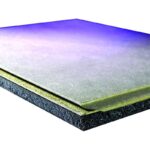

Acoustic MDF

When you need the noise to stay out, you need Acoustic MDF to step in. The panels are perforated at the factory or slotted and paired with insulation backing to absorb or diffuse ambient noise. These boards are excellent for use in theatres, studios, offices, cinemas, and any other setting where acoustic intervention matters.

Bead and Butt MDF

Bead and Butt, also called the Richmond profile, features evenly spaced, rounded beads, separated by flat rails. You get that classic, shaker-inspired look that imitates traditional wainscoting without the cost and complexity of real wood.

V-Groove

The V-Grooved panels have a distinctive and crisp V-shaped cut that can form both horizontal and vertical patterns. The profile looks more modern and geometric, while still introducing depth and shadow lines.

Large MDF Boards

For projects that call for fewer joins or CNC detailing, oversized MDF boards (for example, 3050mm x 1220mm or larger) reduce waste and improve workflow. They’re heavy during handling, but save time when cutting large spans or continuous panels.

Why Buyers Choose Our MDF

Flawless Finish and Machinability

Our MDF is sanded smooth and consistent with virtually no voids, grain, or knots. It is perfect for veneering, routing, painting, and other customisations, delivering a premium finish every time.

Dimensionally Stable and Versatile

MDF is built to be dead flat, holding its shape under humidity changes when sealed. It is best suited for precise interior applications like worktops, mouldings, cabinetry, etc.

Cost-Effective Compared to Alternatives

MDF is often more affordable and reliable than plywood, especially for projects using paint-grade or veneered surfaces. Our trade pricing and volume discounts mean even better value for larger orders.

Trade and DIY Friendly

Our customers rate us highly on Trustpilot and Review io for clear communication, fast delivery, and reliable services. They also mention how well the materials worked for their projects.

Tips for Choosing and Working with MDF

Machine with care– It is recommended to use solid carbide or PCD cutters at normal speeds. Finish pilot-drilling the screw holes to avoid edge splitting.

Health considerations– Control dust aggressively, as it contains formaldehyde and adhesive particles that could irritate your respiratory system. Use a LEV system, an FFP3 mask with an organic vapour filter and a HEPA vacuum for safety.

Seal all surfaces– The edges and cutouts, especially, can release formaldehyde emissions and allow moisture to enter. We have MDF edge taping that you can use to mitigate this.

Know your standards– Look for European E1/E0 or CARB Phase 2, ULEF/NAF variants certification to ensure low VOC emissions.

Common Uses of MDF Board

MDF board is used in several home and professional projects, including;

- Furniture

- Flooring

- Doors and windows frames

- Shelving

- Cabinets

- Wainscoting

- Decorative projects

- Tradeshow booths and theatre set construction

- Speaker boxes etc.

Pros of MDF

- Generally inexpensive compared to wood or plywood

- It doesn’t have splinters or voids, so it provides consistent surface

- Its smooth surface makes it possible to paint

- Effortless to cut using band saw, jigsaw, screw saw with no tearing out or splinting

Cons

- It is vulnerable to moisture, so it swells if exposed to water.

- It is very heavy compared to plywood

- Since it soaks up the stain, it cannot be stained.

- Doesn’t have wood grains for beauty like wood.

- Since it is made of small particles, doesn’t hold the screws perfectly.

- It contains urea-formaldehyde so one should be careful when cutting it to avoid inhaling the particles.

FAQs

Can you paint MDF?

Yes, MDF takes paint well, but you should use primer, and preferably one that’s solvent-based or shellac-based, to seal the edges and surfaces. It prevents the MDF from absorbing too much moisture and delivers a durable finish.

How is MDF made?

MDF is made by breaking down hardwood or softwood residuals into wood fibres. The fibres are then combined with wax and a resin binder and pressed under high temperatures to create dense, uniform boards that are ideal for furniture and construction applications.

What is MDF made from?

MDF is the product of wood fibres, commonly from softwoods, that are combined with resin and wax. They are then compressed and heated to form solid panels.

What is MDF used for?

MDF is commonly used in furniture, shelving, cabinetry, wall panelling, moulding, and other applications. It’s valued for its smooth surface, which takes paint and veneer nicely, and its stability, which prevents cracking or warping, compared to solid wood.

Is MDF sustainable?

MDF can be considered somewhat sustainable, given that it is made from recycled wood fibres and wood waste. However, depending on the manufacturer, the product may use adhesives that contain formaldehyde, a potential pollutant. Eco-friendlier options with low-emission ingredients are available, but recycling MDF can be challenging. Check for certified products (e.g., FSC-certified MDF) to be sure.

Conclusion

Applied well and in the right place, MDF is, undoubtedly, the best sheet material to use for most home and professional applications.

Showing 1–32 of 451 results

-

CT1 Sealant & Construction Adhesive 290ml

If you have been in the market long, this is a CT1 Adhesive, the most known top-quality adhesive in the market. It sticks anything to anything and you cannot go wrong with it. Works in wet and underwater conditions and is UV-resistant & solvent-free.

From:£10.90£13.08Ex VATInc VAT Add to cart -

ProDec Contractor Skeleton Caulking Gun

This is a standard Skeleton Caulking Gun for Applying 400 ml and 310 ml adhesive cartridges.

£4.61£5.53 Ex VATInc VAT Add to cart -

2mm Finsa MDF Board 2440mm x 1220mm (8′ x 4′) FSC®

MDF 2mm is a composite panel product consisting of cellulosic fibres compressed with a synthetic resin or other ideal bonding system and joined together under extreme heat and pressure. For light carpentry projects, such as shelving and trim, 2mm MDF can be excellent.

£6.91£8.29 Ex VATInc VAT Add to cart -

2.5mm Finsa MDF Board 2440mm x 1220mm (8′ x 4′) FSC® Pack of 288

MDF 2.5mm is a composite panel product consisting of cellulosic fibres compressed with a synthetic resin or other ideal bonding system and joined together under extreme heat and pressure. For light carpentry projects, such as shelving and trim, 2.5mm MDF can be excellent.

£1,423.00£1,707.60 Ex VATInc VAT£4.94£5.93 Per Sheet Add to cart -

3mm White Painted MDF 2440mm x 1220mm (8′ x 4′) FSC®

MDF is an interior board free from natural defects with a smooth sanded surface for precision finishes. This MDF has a clean, attractive white face ideal for joinery jobs like wardrobe and cabinet making, shelving and bookcases.

£10.19£12.23 Ex VATInc VAT Add to cart -

3mm Premium MDF Board 2440mm x 1220mm (8′ x 4′) FSC®

MDF 3mm is a composite panel product consisting of cellulosic fibres compressed with a synthetic resin or other ideal bonding system and joined together under extreme heat and pressure. For light carpentry projects, such as shelving and trim, 3mm MDF can be excellent.

Original price was: £7.75 Ex VAT (£9.30 Inc VAT).£5.75£6.90Current price is: £5.75 Ex VAT (£6.90 Inc VAT). Ex VATInc VAT Add to cart -

3mm Black Painted MDF 2440mm x 1220mm (8′ x 4′) FSC®

3mm black painted MDF is a sheet that primarily is used for interior decorative purposes. It has no natural defects and a smooth sanded surface for detailed finishes. This 3mm black MDF has a flawless, clean and attractive black face ideally used for joinery jobs like wardrobe and cabinet making, shelving and bookcases.

Original price was: £10.81 Ex VAT (£12.97 Inc VAT).£9.67£11.60Current price is: £9.67 Ex VAT (£11.60 Inc VAT). Ex VATInc VAT Add to cart -

3mm MDF Board 3050mm x 1220mm (10′ x 4′) FSC® Pack of 240

MDF 3mm 3050×1220 is a composite panel product consisting of cellulosic fibres compressed with a synthetic resin or other ideal bonding system and joined together under extreme heat and pressure. For light carpentry projects, such as shelving and trim, 3mm MDF can be excellent.

£2,258.24£2,709.89 Ex VATInc VAT£9.41£11.29 Per Sheet Add to cart -

3mm Medite Premier MDF 2440mm x 1220mm (8′ x 4′) FSC®

3mm Medite Premier is a multi-purpose MDF from our premium range. It has a smooth surface, consistent thickness and is made for clean finishes. Can be used to make furniture, machining, shelving and more.

£10.71£12.85 Ex VATInc VAT Add to cart -

3mm Medite Premier MDF 3050mm x 1220mm (10′ x 4′) FSC®

3mm Medite Premier is a multi-purpose MDF from our premium range. It has a smooth surface, consistent thickness and is made for clean finishes. Can be used to make furniture, machining, shelving and more.

Original price was: £14.99 Ex VAT (£17.99 Inc VAT).£12.27£14.72Current price is: £12.27 Ex VAT (£14.72 Inc VAT). Ex VATInc VAT Add to cart -

Buy in Bulk & Save

25-49 50+ £57.71£69.25 £54.68£65.62 There are 2 more images4mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Oak MDF sheets 4mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 4mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£60.75£72.90 Ex VATInc VAT Add to cart -

4mm Premium MDF Board 2440mm x 1220mm (8′ x 4′) FSC®

MDF 4mm is a composite panel product consisting of cellulosic fibres compressed with a synthetic resin or other ideal bonding system and joined together under extreme heat and pressure. For light carpentry projects, such as shelving and trim, 4mm MDF can be excellent.

Original price was: £12.19 Ex VAT (£14.63 Inc VAT).£11.65£13.98Current price is: £11.65 Ex VAT (£13.98 Inc VAT). Ex VATInc VAT Add to cart -

4mm MDF Board 3050mm x 1220mm (10′ x 4′) FSC® Pack of 192

MDF 4mm 3050×1220 is a composite panel product consisting of cellulosic fibres compressed with a synthetic resin or other ideal bonding system and joined together under extreme heat and pressure. For light carpentry projects, such as shelving and trim, 4mm MDF can be excellent.

£2,451.05£2,941.26 Ex VATInc VAT£12.77£15.32 Per Sheet Add to cart -

4mm Medite Tricoya Extreme MDF 2440mm x 1220mm (8′ x 4′) FSC®

4mm Medite Tricoya Extreme MDF is a premium high moisture-resistant board that is mostly used for CNC work, painting and external applications. It is commonly used for underground works and is super dense, with a very smooth surface. This is the most advanced board on the market offering 25 years in ground and 50 years above ground guarantee by manufacturer.

£88.82£106.58 Ex VATInc VAT Add to cart -

4mm Medite Premier MDF 2440mm x 1220mm (8′ x 4′) FSC®

4mm Medite Premier is a multi-purpose MDF from our premium range. It has a smooth surface, consistent thickness and is made for clean finishes. Can be used to make furniture, machining, shelving and more.

£15.45£18.54 Ex VATInc VAT Add to cart -

4mm Medite Premier MDF 3050mm x 1220mm (10′ x 4′) FSC®

4mm Medite Premier is a multi-purpose MDF from our premium range. It has a smooth surface, consistent thickness and is made for clean finishes. Can be used to make furniture, machining, shelving and more.

£19.05£22.86 Ex VATInc VAT Add to cart -

6mm Premium MDF Board 2440mm x 1220mm (8′ x 4′) FSC®

MDF 6mm is a composite panel product consisting of cellulosic fibres compressed with a synthetic resin or other ideal bonding system and joined together under extreme heat and pressure. For light carpentry projects, such as shelving and trim, 6mm MDF can be excellent.

£9.10£10.92 Ex VATInc VAT Add to cart -

6mm Premium Moisture Resistant MDF Board 2440mm x 1220mm (8′ x 4′) FSC®

Moisture resistant MDF 6mm is particularly suitable for construction applications that need panels, with high load-bearing capacity and moisture resistance and for a wide range of interior applications.

Original price was: £13.05 Ex VAT (£15.66 Inc VAT).£11.95£14.34Current price is: £11.95 Ex VAT (£14.34 Inc VAT). Ex VATInc VAT Add to cart -

Buy in Bulk & Save

15-29 30+ £51.57£61.88 £48.92£58.70 There are 2 more images6mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Oak MDF sheets 6mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 6mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£53.17£63.80 Ex VATInc VAT Add to cart -

6mm Black Walnut Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

The veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. Part of a range of veneers that are similar in quality to that of veneered Plywood, this full sheet of Black Walnut MDF is a stunning, darker hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£74.97£89.96 Ex VATInc VAT Add to cart -

6mm Fire Rated MDF Board Euroclass B 2440mm x 1220mm (8′ x 4′) FSC®

Fire Rated MDF 6mm is ideal for use in internal dry conditions for non-structural applications and suitable for services such as display panes, wall linings, partitions, and so on. This Product is CARB 2 Compliant & has top-level of machining and finishing properties.

£22.02£26.42 Ex VATInc VAT Add to cart -

6mm Double-sided White Melamine Faced MDF 2440mm x 1220mm (8′ x 4′) FSC®

6mm Non-Textured Double-Sided White Melamine Faced MDF formed by covering an MDF core with a decorative resin-impregnated paper, 6mm melamine-faced MDF is suitable for use in high-quality furniture and interior design projects. The core of the material is composed of wood fibres, giving a flat and smooth surface, high density and stability, which makes it excellent for processing.

£24.95£29.94 Ex VATInc VAT Add to cart -

6mm Finsa Fibrapan Hidrofugo Moisture Resistant MDF 2440mm x 1220mm (8′ x 4′) FSC®

6mm Finsa Hidrofugo Moisture resistant MDF currently is the number one choice for rout jobs, painting and furniture making. Finsa Fibrapan Hidrofugo 6mm has a flat and consistent surface with a dense core to allow a high standard for machining, giving a straight cut on each piece giving you a perfect optimal smooth finish.

£19.83£23.80 Ex VATInc VAT Add to cart -

6mm Flexible MDF Cross Grain 1220mm x 2440mm (4′ x 8′) FSC®

6mm Flexible MDF Cross Grain is a multi-purpose MDF, produced using superior wood refining technology and specially designed resins. Its main applications include contemporary and reproduction furniture, children’s toys, snooker tables, shopfitting, hi-fi speaker cabinets and doors.

£28.48£34.18 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

60-119 120+ £27.06£32.47 £24.21£29.05 There are 1 more images6mm Flexible MDF Long Grain 2440mm x 1220mm (8′ x 4′) FSC®

6mm Flexible MDF Long Grain is a multi-purpose MDF, produced using superior wood refining technology and specially designed resins. Its main applications include contemporary and reproduction furniture, children’s toys, snooker tables, shopfitting, hi-fi speaker cabinets and doors.

£28.48£34.18 Ex VATInc VAT Add to cart -

6mm Fire Rated MDF Board Euroclass B 3050mm x 1220mm (10′ x 4′) FSC® Pack of 120

Fire Rated MDF 6mm is ideal for use in internal dry conditions for non-structural applications; suitable for uses such as display panes, wall linings, partitions, and so on.

£2,634.24£3,161.09 Ex VATInc VAT£21.95£26.34 Per Sheet Add to cart -

Buy in Bulk & Save

25-49 50+ £69.24£83.09 £65.59£78.71 There are 1 more images6mm Maple Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Maple MDF sheets 6mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 6mm maple veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£72.88£87.46 Ex VATInc VAT Add to cart -

6mm Finsa Fibrapan Hidrofugo Moisture Resistant MDF 3050mm x 1220mm (10′ x 4′) FSC® Pack of 120

6mm 3050x1220mm Finsa Hidrofugo Moisture resistant MDF currently is the number one choice for rout jobs, painting and furniture making. Finsa Fibrapan Hidrofugo 6mm 3050x1220mm has a flat and consistent surface with a dense core to allow a high standard for machining, giving a straight cut on each piece giving you a perfect optimal smooth finish.

£2,376.20£2,851.44 Ex VATInc VAT£19.80£23.76 Per Sheet Add to cart -

Buy in Bulk & Save

25-49 50+ £47.20£56.64 £44.71£53.65 There are 1 more images6mm Ash Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

6mm Ash veneered MDF sheets offer a high standard of durability and are perfect for your furniture projects. Each 6mm veneered board can be used in multiple applications, ensuring a flawless finish from every angle. Whether used for cabinetry, shelving, or wardrobe, the natural grain patterns of Ash will be seen. 6mm Ash veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

£49.68£59.62 Ex VATInc VAT Add to cart -

6mm Oak Veneered MDF 2 Sides Crown Cut A/B Natural Grade 3050mm x 1220mm (10′ x 4′) Pack of 30

Oak MDF Finsa sheets 6mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The board is 036 natural grade meaning it has; some colour variation, natural defects and narrower leafs. You may expect multiple boards to be different from each other a little more than how they come with select grade. The 6mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£1,754.99£2,105.99 Ex VATInc VAT£58.50£70.20 Per Sheet Add to cart -

6mm Medite Tricoya Extreme MDF 2440mm x 1220mm (8′ x 4′) FSC®

6mm Medite Tricoya Extreme MDF is a premium high moisture-resistant board that is mostly used for CNC work, painting and external applications. It is commonly used for underground works and is super dense, with a very smooth surface. This is the most advanced board on the market offering 25 years in ground and 50 years above ground guarantee by manufacturer.

£112.35£134.82 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

25-49 50+ £65.20£78.24 £61.77£74.12 There are 2 more images6mm Cherry Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

The veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. Part of a range of veneers that are similar in quality to that of veneered Plywood, this full sheet of 6mm Cherry MDF is a stunning, pinkish hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£68.63£82.36 Ex VATInc VAT Add to cart