Veneered MDF

Most people understand MDF (Medium Density Fibreboards) but don’t know much about veneered MDF. Here, you will learn more about veneered boards, various applications to use them and why Veneered MDF suits many different projects, where a clean, natural finish is needed.

What is veneered MDF?

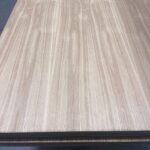

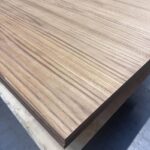

Veneered MDF board is manufactured from high-quality wood veneers firmly attached to medium density fibreboards. Usually, the panels have 0.5mm veneer coating on the two sides.

Although the veneer finish meant to simulate typical solid wood, there are other reasons for utilising veneer coat on MDF. Thanks to the veneer finish, the designers can develop wood variations used in the same way as natural wood. Generally, these options are given to the clients as cost-effective and safer options since the veneer coat protects the fibreboard and makes it safe for use.

Typically, Veneered MDF panels are produced in different face grades. Most boards come with a higher grade on the front and slightly lower grade on the back, often referred to as A/B faces. The top layer is real timber veneer, which gives the panel its natural grain, warm colour and familiar character of wood. The MDF core keeps the sheet stable and smooth, so it handles well during cutting and fitting. Because of this combination, Veneered Medium Density Fibreboard offers the look of solid wood in a lighter and more consistent form. Builders often choose it when they need a natural finish at more a practical cost, making it a reliable option for furniture, wall panels and many interior projects.

Advantages of veneered boards

Sheet Materials Wholesale provides veneered MDF panels that combine a smooth MDF core and a real timber face.

Here are the advantages of veneered sheets;

- Veneered boards are made from MDF with a natural wood veneer applied to the surface.

- They provide more stability compared to solid wood and are less vulnerable to fluctuations in humidity and heat. So, unlike solid wood, which bends and warps over time, MDF veneer sheets don’t twist and remain straight throughout their lifespan.

- Its dimensional stability helps the board stay flat and consistent during use. The surface of veneered MDF is even and consistent, which helps during measuring, cutting and general handling.

- MDF veneer sheets are easy to sand and, therefore, easy to use.

- Veneered boards also allow easy application of glue, screws and paints. As such, you can easily DIY and make your office or domestic furniture.

- Lastly, the boards can be cut into different shapes and forms. It allows you to customise your furniture.

Applications of the veneered MDF panels

In most cases, veneered MDF utilised in internal applications. The boards used in domestic functions such as:

- Making of the office furniture;

- Panel moulding;

- Fitting of kitchen cabinets;

- Making of fire surrounds;

- Assembly of dining sets.

Because of the smooth characteristic of MDF veneer sheets, they highly sought after sheets for decorations.

Why choose our veneered MDF?

- Veneered MDF sheets come in a wide choice of practical thicknesses, typically 4-31mm, with standard sheet size 2440 x 1220mm and 3050 x 1220mm.

- Each board is designed for interior use and comes with square edges, low formaldehyde emissions (E1 or E05) and consistent veneer quality.

- A/B grade boards are available when both sides of the sheet need a clean finish.

- The full Veneered MDF range is available online, so you can browse timber species, check dimensions and compare Veneered MDF prices before ordering.

- Whether you need a single sheet or a pallet quantity, we provide value for money, competitive prices and clear volume pricing.

- Samples are available on many species and thicknesses, depending on the product.

- Sheet Materials Wholesale holds UK stock of Veneered MDF boards, meaning quick dispatch and reliable availability.

- We supply Veneered boards nationwide, offering fast UK delivery and next day options on selected items. Delivery is available to homes, workshops or building sites, and kerbside delivery can be arranged for larger projects.

- Sheet Materials Wholesale provides straightforward service, good pricing and full nationwide coverage.

- VAT invoices are included with all orders, and full order tracking is provided as standard.

- Trade and DIY customers have access to pallet quantities, trade discounts and competitive wholesale rates.

- You can place bulk orders, request a fast quote or order single sheets online in minutes.

FAQ

Where to buy Veneered MDF?

You can buy Veneered MDF online at Sheet Materials Wholesale. We hold UK stock, offer competitive prices and deliver nationwide.

How to finish Veneered MDF?

Sand lightly, remove dust, then apply varnish, oil or wax. Veneered MDF finishes well and keeps a natural timber look.

How to paint Veneered MDF?

Use a primer first, let it dry, then apply two coats of paint. Smooth sanding between coats gives the best result.

Can you stain Veneered MDF?

Yes. Veneered MDF has a real wood surface, so it can be stained. Apply a wood stain evenly, then seal with clear varnish.

What is Veneered MDF used for?

Veneered MDF is used for furniture, cabinetry, shelving, wall panels and decorative interior work. It gives a real-wood appearance with the stability of MDF.

Showing 1–32 of 73 results

-

Buy in Bulk & Save

25-49 50+ £57.71£69.25 £54.68£65.62  There are 2 more images

There are 2 more images4mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Oak MDF sheets 4mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 4mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£60.75£72.90 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

15-29 30+ £51.57£61.88 £47.85£57.42  There are 2 more images

There are 2 more images6mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Oak MDF sheets 6mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 6mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£53.17£63.80 Ex VATInc VAT Add to cart -

6mm Black Walnut Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

The veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. Part of a range of veneers that are similar in quality to that of veneered Plywood, this full sheet of Black Walnut MDF is a stunning, darker hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£74.97£89.96 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

25-49 50+ £69.24£83.09 £65.59£78.71  There are 1 more images

There are 1 more images6mm Maple Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Maple MDF sheets 6mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 6mm maple veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£72.88£87.46 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

25-49 50+ £47.20£56.64 £44.71£53.65 There are 1 more images6mm Ash Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

6mm Ash veneered MDF sheets offer a high standard of durability and are perfect for your furniture projects. Each 6mm veneered board can be used in multiple applications, ensuring a flawless finish from every angle. Whether used for cabinetry, shelving, or wardrobe, the natural grain patterns of Ash will be seen. 6mm Ash veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

£49.68£59.62 Ex VATInc VAT Add to cart -

6mm Oak Veneered MDF 2 Sides Crown Cut A/B Natural Grade 3050mm x 1220mm (10′ x 4′) Pack of 30

Oak MDF Finsa sheets 6mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The board is 036 natural grade meaning it has; some colour variation, natural defects and narrower leafs. You may expect multiple boards to be different from each other a little more than how they come with select grade. The 6mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£1,754.99£2,105.99 Ex VATInc VAT£58.50£70.20 Per Sheet Add to cart -

Buy in Bulk & Save

25-49 50+ £65.20£78.24 £61.77£74.12 There are 2 more images6mm Cherry Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

The veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. Part of a range of veneers that are similar in quality to that of veneered Plywood, this full sheet of 6mm Cherry MDF is a stunning, pinkish hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£68.63£82.36 Ex VATInc VAT Add to cart -

6mm Ash Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′) Pack of 30

6mm Ash veneered MDF sheets offer a high standard of durability and are perfect for your furniture projects. Each 6mm veneered board can be used in multiple applications, ensuring a flawless finish. Whether used for cabinetry, shelving, or wardrobe, the natural grain patterns of Ash will be seen. With a high-quality reverse ash veneer, these sheets have “A” grade face with a “B” reverse that may show natural variation.

£1,099.85£1,319.82 Ex VATInc VAT£36.66£43.99 Per Sheet Add to cart -

Buy in Bulk & Save

12-24 25+ £77.55£93.06 £73.47£88.16  There are 2 more images

There are 2 more images6mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 3050mm x 1220mm (10′ x 4′)

Oak MDF sheets 6mm 10×4 glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 6mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£81.63£97.96 Ex VATInc VAT Add to cart -

6mm Pine Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Pine MDF sheets 6mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 6mm pine veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF

£55.79£66.95 Ex VATInc VAT Add to cart -

6mm Sapele Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

The veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. This full sheet of 6mm Sapele MDF is a stunning, light brown tone hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£53.59£64.31 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

12-23 24+ £53.34£64.01 £51.10£61.32 There are 2 more images10mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Oak MDF sheets 10mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 10mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£56.15£67.38 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

12-23 24+ £74.10£88.92 £68.75£82.50 There are 1 more images10mm Black Walnut Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

The 10mm veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. Part of a range of veneers that are similar in quality to that of veneered Plywood, this full sheet of 10mm Black Walnut MDF is a stunning, darker hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£76.39£91.67 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

12-23 24+ £49.05£58.86 £46.47£55.76 There are 1 more images10mm Ash Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

10mm Ash veneered MDF sheets offer a high standard of durability and are perfect for your furniture projects. Each 10mm veneered board can be used in multiple applications, ensuring a flawless finish from every angle. Whether used for cabinetry, shelving, or wardrobe, the natural grain patterns of Ash will be seen. With a high-quality reverse ash veneer, these sheets have “A” grade face with a “B” reverse that may show natural variation.

£51.63£61.96 Ex VATInc VAT Add to cart -

10mm Oak Veneered MDF 2 Sides Crown Cut A/B Natural Grade 3050mm x 1220mm (10′ x 4′) Pack of 24

Walnut MDF Finsa sheets 10mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The board is 036 natural grade meaning it has; some colour variation, natural defects and narrower leafs. You may expect multiple boards to be different from each other a little more than how they come with select grade. The 10mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£1,512.95£1,815.54 Ex VATInc VAT£63.04£75.65 Per Sheet Add to cart -

10mm Ash Veneered MDF 2 Sides Crown Cut A/B Natural Grade 3050mm x 1220mm (10′ x 4′) Pack of 24

10mm Ash veneered MDF sheets offer a high standard of durability and are perfect for your furniture projects. Each 10mm veneered board can be used in multiple applications, ensuring a flawless finish from every angle. Whether used for cabinetry, shelving, or wardrobe, the natural grain patterns of Ash will be seen. Ash veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

£1,248.81£1,498.57 Ex VATInc VAT£52.03£62.44 Per Sheet Add to cart -

10mm Pine Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Pine MDF sheets 10mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 10mm pine veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF

£48.55£58.26 Ex VATInc VAT Add to cart -

10mm Pine Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′) Pack of 24

Pine MDF sheets 10mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 10mm pine veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF

£817.21£980.65 Ex VATInc VAT£34.05£40.86 Per Sheet Add to cart -

Buy in Bulk & Save

25-49 50+ £75.86£91.03 £71.87£86.24  There are 1 more images

There are 1 more images10mm Maple Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Maple MDF sheets 10mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 10mm maple veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£79.85£95.82 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

12-23 24+ £59.40£71.28 £55.69£66.83 There are 2 more images13mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Oak MDF sheets 13mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 13mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£61.88£74.26 Ex VATInc VAT Add to cart -

13mm Black Walnut Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

The 13mm veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. Part of a range of veneers that are similar in quality to that of veneered Plywood, this full sheet of 13mm Black Walnut MDF is a stunning, darker hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£76.65£91.98 Ex VATInc VAT Add to cart -

13mm Black Walnut Veneered MDF 2 Sides Crown Cut A/B Select Grade 3050mm x 1220mm (10′ x 4′) Pack of 24

Walnut MDF Finsa sheets 13mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The board is 035 Select grade meaning it has; Less colour variation, less natural defects and wider leafs. You may expect multiple boards to be more similar looking than with natural grade. The 13mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£2,297.63£2,757.16 Ex VATInc VAT£95.73£114.88 Per Sheet Add to cart -

13mm Oak Veneered MDF 2 Sides Crown Cut A/B Natural Grade 3050mm x 1220mm (10′ x 4′) Pack of 24

Walnut MDF Finsa sheets 13mm glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The board is 036 natural grade meaning it has; some colour variation, natural defects and narrower leafs. You may expect multiple boards to be different from each other a little more than how they come with select grade. The 13mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£1,650.23£1,980.28 Ex VATInc VAT£68.76£82.51 Per Sheet Add to cart -

13mm Ash Veneered MDF 2 Sides Crown Cut A/B Natural Grade 3050mm x 1220mm (10′ x 4′) Pack of 24

13mm Ash veneered MDF sheets offer a high standard of durability and are perfect for your furniture projects. Each 13mm veneered board can be used in multiple applications, ensuring a flawless finish from every angle. Whether used for cabinetry, shelving, or wardrobe, the natural grain patterns of Ash will be seen. With a high-quality reverse ash veneer, has “A” grade face with a “B” reverse that may show natural variation.

£1,361.98£1,634.38 Ex VATInc VAT£56.75£68.10 Per Sheet Add to cart -

Buy in Bulk & Save

13-24 25+ £78.02£93.62 £73.92£88.70  There are 1 more images

There are 1 more images13mm Maple Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Maple MDF sheets 13mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 13mm maple veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£82.13£98.56 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

12-24 25+ £88.51£106.21 £83.85£100.62 There are 2 more images13mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 3050mm x 1220mm (10′ x 4′)

Oak MDF sheets 13mm 10×4 glued to the wood surface increases the beauty and charm of the furniture that no other decorative panels can. The 13mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£93.17£111.80 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

12-24 25+ £54.01£64.81 £51.17£61.40 There are 1 more images13mm Ash Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

13mm Ash veneered MDF sheets offer a high standard of durability and are perfect for your furniture projects. Each 13mm veneered board can be used in multiple applications, ensuring a flawless finish from every angle. Whether used for cabinetry, shelving, or wardrobe, the natural grain patterns of Ash will be seen. With a high-quality ash veneer the sheet has “A” grade face with a “B” reverse that may show natural variation.

£56.85£68.22 Ex VATInc VAT Add to cart -

13mm Pine Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Pine MDF sheets 13mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 13mm pine veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF

£63.19£75.83 Ex VATInc VAT Add to cart -

13mm Sapele Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′)

13mm Sapele veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. This full sheet of 13mm Sapele MDF is a stunning, light brown tone hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£62.98£75.58 Ex VATInc VAT Add to cart -

16mm Oak Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′) Pack of 24

Oak MDF sheets 16mm glued to the wood surface increase the beauty and charm of the furniture, which no other decorative panels can. The 16mm veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£1,241.94£1,490.33 Ex VATInc VAT£51.75£62.10 Per Sheet Add to cart -

16mm Black Walnut Veneered MDF 2 Sides Crown Cut A/B 2440mm x 1220mm (8′ x 4′) Pack of 24

The 16mm veneered MDF has been made with a thin layer of hardwood, bonded to standard MDF, producing a smooth and stable surface. Part of a range of veneers that are similar in quality to that of veneered Plywood, this full sheet of 16mm Black Walnut MDF is a stunning, darker hardwood that can be used for cabinets, furniture, decorative panel mouldings, bookshelves and more.

£1,673.71£2,008.45 Ex VATInc VAT£69.74£83.69 Per Sheet Add to cart -

Buy in Bulk & Save

25-49 50+ £84.38£101.26 £82.00£98.40  There are 1 more images

There are 1 more images16mm Maple Veneered MDF 2 Sides Crown Cut A/B Grade 2440mm x 1220mm (8′ x 4′)

Maple MDF sheets 16mm glued to the wood surface increase the beauty and charm of the furniture that no other decorative panels can. The 16mm maple veneered MDF has “A” grade face with a “B” reverse that may show natural variation.

Veneered MDF (A/B) is made up of quality natural wood veneers bonded to premium MDF.

£86.77£104.12 Ex VATInc VAT Add to cart