OSB Board

OSB board is one of the most-used material sheets in various applications. But what makes it the most preferred construction sheet material by most builders? Continue reading below to find out, including different types of OSB, and where they are commonly used.

What is OSB?

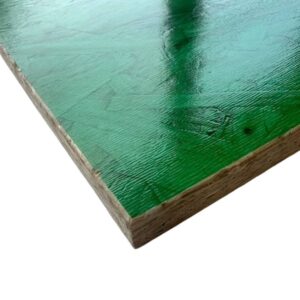

Perhaps you are wondering what the heck the OSB stands for. Well, it stands for Oriented Strand Board. OSB sheet is a strong, versatile and reliable engineered sheet material designed to be used in a myriad of applications such as flooring and roofing, especially in areas of high humidity.

OSB wood sheet is manufactured by use of adhesives and layers of strands of wood (hence the name). It is these strands that give OSB its unique appearance.

OSB panel typically has a particoloured and rough surface. In fact, the individual strips of wood utilised during the creation of OSB are visible. The trips are usually 1 inch by 5.9 inches. The wood strips are laid disproportionately crisscrossing each other in different thickness and types. This is the secret behind OSB’s strength and flexibility.

OSB is also used as an alternative to softwood plywood since it offers the same performance, but cheaper than plywood. As such, OSB is commonly used as sheathing materials on floors, ceilings and walls in today’s construction.

Types of OSB Board

There are four main types of OSB wood sheets. The classification is usually done based on their physical features.

OSB/1

This type of OSB is used for general applications but in dry conditions only. The strand board is fixed together using UF glue (Urea Formaldehyde).

It is used in non-structural applications, making furniture, in decorations and packaging.

Sterling Board/OSB2

Sterling board is a perfectly-engineered wood sheet ideal for structural application in dry load-bearing conditions. PMDI (Isocyanate) glue is used for the core, while MUF (Melamine-Urea-Formaldehyde) is used for the outer wood strips.

A low-cost and perfect alternative to plywood, OSB 2 is used in applications such as roofing, making furniture, packaging, flooring, decoration, walls and pallets.

Sterling OSB3

Sterling board OSB 3 is made to withstand the toughest (humid) conditions. It is a perfect-engineered sheet material meant for structural applications in load-bearing and harsh conditions. The wood strips are bound together using PF (Phenol-Formaldehyde) glue.

OSB 3 is utilised in applications such as roofing, wall sheathing, packaging, flooring and signboards.

OSB 4

This is generally termed as a heavy-duty load-bearing Oriented Strand Board. Just like OSB 3, OSB 4 is also used in harshest/humid conditions. The glue used is PF (Phenol-Formaldehyde).

OSB 4 is used as a structural panel in applications such as flooring and subflooring, roofing, wall sheathing, I-beams and in structural elements.

Common Uses of OSB Sheet

Here are the common applications of OSB board.

Used As Flooring Materials

A variety of sheet materials can be utilised in flooring. They include tiles, plywood, wooden boards and OSB. However, OSB offers the best flooring. But it all depends on the homeowner’s preferences. For those who want a cost-effective flooring material, OSB panel is, undoubtedly, a go for option.

Used As Sheets for Walls

OSB, concrete, plywood and hardwood are all used in making walls. However, OSB tongue and groove is preferred due to its pocket-friendly cost and considerable strength. Besides, OSB sheets make the interior to look more natural compared to the other wall materials.

Roof Sheathing

Seamed metal, cedarwood and corrugated metals are used as roofing materials. However, the OSB board is an excellent addition since it adds a more natural vibe to the structure. It is also relatively inexpensive compared to the other materials, but it is affected by extreme weather elements.

Making Furniture

OSB wood is utilised in making furniture like tables and chairs. In most cases, furniture made of hardwood needs furnishing and painting. However, with OSB wood sheet, painting is unnecessary.

FAQ

How to protect OSB3 from rain?

The OSB3 board is moisture resistant, but don’t leave it soaking. Store the sheets off the ground. Cover them so rain can run off. Keep air gaps around the stack. Short rain is fine. Standing water is not.

Is OSB3 stronger than plywood?

Plywood is generally stronger and stiffer than OSB3. OSB3 is chosen mainly for its lower cost while still meeting structural requirements for walls, roofs and flooring.

How is OSB3 board made?

OSB3 is created by pressing wood strands together with waterproof resin under heat. The strands are laid in different directions to add strength across the sheet. That gives the OSB board a solid, even structure and a reliable finish at a good OSB3 board price.

What is OSB3 board used for?

For roofs, walls, flooring, sheds, hoardings and general construction work. It suits structural jobs, interior builds and exterior projects when sealed. Many builders choose OSB3 sheet because it’s strong, stable and cost effective.

Can OSB3 board be painted?

Yes, you can paint OSB3. Just prime it first to stop the texture showing through. A good primer and two coats of paint will tidy the surface and add light protection. Lots of people paint OSB3 sheets for sheds, workshops and interior builds.

Conclusion

Cost-effective, versatile, strong and sustainable, OSB board is certainly a go for option when choosing the best sheet material for roofing, flooring or making of furniture.

Showing all 19 results

-

9mm SmartPly OSB 3 Board 2397mm x 1197mm (7.86′ x 3.92′) FSC®

9mm OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

£10.39£12.47 Ex VATInc VAT Add to cart -

11mm SmartPly OSB 3 Board 2440mm x 1220mm (8′ x 4′) FSC®

11mm OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

£12.75£15.30 Ex VATInc VAT Add to cart -

12.5mm SmartPly Airtight OSB 3 Board 2397mm x 1197mm (7.86′ x 3.92′) FSC®

Smartply airtight is a high performance osb3 board with built-in vapour control layer and airtight barrier, removing requirement for separate membranes. Certified by the PHI, it offers excellent tape adhesion, strength, and durability for Passivhaus builds. This product has NAF(No added formaldehyde), it’s a sustainable choice for newly build houses and renovations.

£36.61£43.93 Ex VATInc VAT Add to cart -

15mm SterlingOSB Zero OSB 3 Board 2397mm x 1197mm (7.86′ x 3.92′) FSC®

15mm OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

£16.78£20.14 Ex VATInc VAT Add to cart -

15mm EGGER OSB 3 Board 2397mm x 1197mm (7.86′ x 3.92′) FSC®

15mm EGGER OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

£17.77£21.32 Ex VATInc VAT Add to cart -

18mm SmartPly OSB 3 Board 2440mm x 1220mm (8′ x 4′) FSC®

18mm Smartply OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

£18.45£22.14 Ex VATInc VAT Add to cart -

18mm Kronobuild OSB 3 TG4E Tongue And Groove Flooring Board 2440mm x 590mm (8′ x 1.94′) FSC®

18mm OSB 3 with Tongue and Groove profiling is versatile, BBA approved and water-resistant timber panel suitable for load-bearing roofing and flooring applications in dry and humid conditions.

£10.09£12.11 Ex VATInc VAT Add to cart -

18mm SmartPly OSB 3 Primed Site Protect Board 2440mm x 1220mm (8′ x 4′) FSC® Pack of 50

18mm SmartPly is primarily used in the construction industry for different protective applications similar to 18mm hoardboard. 18mm Smartply OSB 3 board is specifically designed for the same use as a hoarding board, temporary fencing, floor, surface protection, and general site area protection. This is a time-saving and durable substitute for 18mm hoardboard ply. 18mm OSB SmartPly one-side primed finish makes it easier to paint or decorate for temporary structures.

£1,461.38£1,753.66 Ex VATInc VAT£29.23£35.08 Per Sheet Add to cart -

18mm EGGER OSB 3 TG4E Tongue And Groove Flooring Board 2400mm x 600mm (8′ x 2′) FSC®

18mm EGGER OSB 3 with Tongue and Groove profiling is versatile, BBA approved and water-resistant timber panel suitable for load-bearing roofing and flooring applications in dry and humid conditions.

£9.95£11.94 Ex VATInc VAT Add to cart -

22mm SmartPly OSB 3 Board 2440mm x 1220mm (8′ x 4′) FSC®

22mm OSB3 or generally called 22mm OSB is an engineered, load-bearing wood-based panel product, free of knots and voids. 22mm Sterling board is suitable for structural use in humid situations.

£28.58£34.30 Ex VATInc VAT Add to cart -

22mm SterlingOSB Zero OSB 3 TG4E Tongue And Groove Flooring Board 2440mm x 590mm (8′ x 1.94′) FSC®

22mm OSB 3 with Tongue and Groove profiling is versatile, BBA approved and water-resistant timber panel suitable for load-bearing roofing and flooring applications in dry and humid conditions.

£14.37£17.24 Ex VATInc VAT Add to cart -

30mm EGGER OSB 4 HDX TG2 Tongue And Groove Flooring Board 2400mm x 675mm (8′ x 2.2′) FSC®

EGGER OSB HDX is a 30mm heavy-duty, load-bearing OSB 4 panel designed for applications to replace a commonly used 38mm Mezzanine Flooring. Its side is wider yet up to 20% lighter, making it easier to install and work with the boards.

£26.19£31.43 Ex VATInc VAT Add to cart -

15mm SmartPly OSB 3 Board 2397mm x 1197mm (7.86′ x 3.92′) FSC®

15mm OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

POA Get a quote -

18mm Swiss Krono OSB 3 TG4E Tongue And Groove Flooring Board 2440mm x 595mm (8′ x 1.95′)

18mm Swiss Krono OSB 3 with Tongue and Groove profiling is versatile, BBA approved and water-resistant timber panel suitable for load-bearing roofing and flooring applications in dry and humid conditions.

POA Get a quote -

18mm SmartPly OSB 3 TG4E Tongue And Groove Flooring Board 2400mm x 600mm (8′ x 2′)

18mm OSB 3 with Tongue and Groove profiling is versatile, BBA approved and water-resistant timber panel suitable for load-bearing roofing and flooring applications in dry and humid conditions.

POA Get a quote -

18mm SterlingOSB Zero OSB 3 Board 2440mm x 1220mm (8′ x 4′) FSC®

18mm Sterling OSB3 2440mm x 1220mm is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

POA Get a quote -

9mm Kronobuild OSB 3 Board 2397mm x 1197mm (7.86′ x 3.92′) FSC®

OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

POA Get a quote -

11mm Kronobuild OSB 3 Board 2440mm x 1220mm (8′ x 4′) FSC®

11mm OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

POA Get a quote -

15mm SmartPly OSB 3 Board 2440mm x 1220mm (8′ x 4′) FSC®

15mm OSB3 is an engineered, load-bearing wood-based panel product, free of knots and voids, and suitable for structural use in humid situations.

POA Get a quote