Buffalo Board

Buffalo board is a tough, anti-slip phenolic plywood sheet from the Buffalo brand, used when you need a strong, safe walking surface. It works in places where standard plywood fails. Builders in the UK choose buffalo boards for lorry decks, ramps, stages, trailers and busy work areas. It delivers grip, strength and long life in all weather conditions.

What is buffalo board?

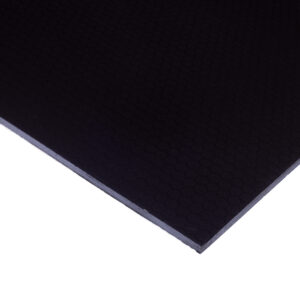

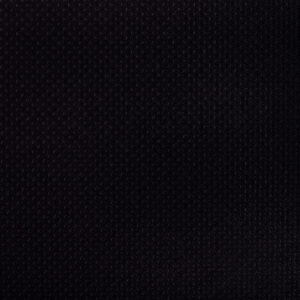

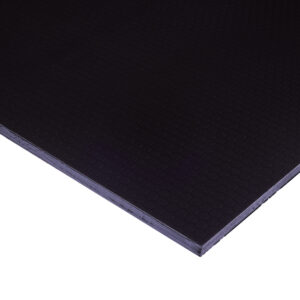

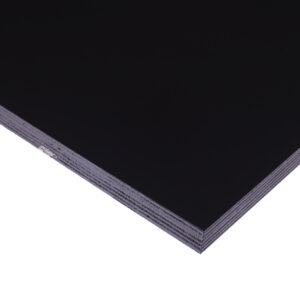

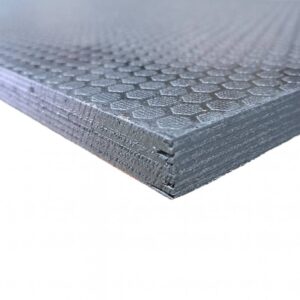

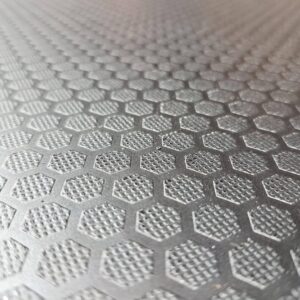

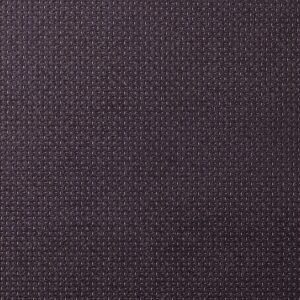

Buffalo board is a Buffalo brand phenolic plywood sheet with a hard protective coating and a non-slip mesh surface. The textured surface keeps footing secure. It works well when the surface is wet or messy. Layers of wood are pressed together to form a solid core. This keeps the board stiff under load. Buffalo board is typically produced with a birch plywood core, which contributes to its strength and durability. The top side is anti-slip. The back is smooth. Buffalo board is designed for demanding outdoor and transport jobs. You will see it in lorry floors, trailer decks, working platforms and public walkways. It is built to last, resist wear and stay safe underfoot.

What is buffalo board used for?

Buffalo board is chosen for jobs where slipping is not an option and surfaces take a real beating. It is not a decorative plywood. It is a working material, built for movement, weight and rough conditions.

In transport, it is most often used for lorry floors, trailers and vans. People walk on it. Loads slide across it. The surface stays steady, even when boots are wet or the floor is dirty. That is why it shows up in plant trailers, service vehicles and horse boxes.

On building sites and access routes, buffalo board solves a simple problem. It gives people confidence underfoot. You will find it on ramps, working platforms and temporary walkways, especially where mud, rain and traffic are part of the day.

It also works well in public and event spaces. Stages, backstage routes and grandstand access areas need grip without constant replacement. Buffalo board handles footfall, wear and changing weather without fuss.

For workshops, farms and utility spaces, it offers a tough floor that lasts. Built for daily use. Designed to take wear. Where safety matters and surfaces get abused, buffalo board earns its place.

In short, this material is a practical choice. It works in jobs where ordinary plywood simply does not cope.

Benefits of buffalo board

Builders choose buffalo board for one simple reason. It does not slip. The surface holds grip underfoot, even in wet or messy conditions. That makes everyday movement safer. It also feels solid. The layered plywood build creates a firm base that holds its shape under weight. This is important on vehicle floors, ramps and platforms, where pressure is constant, and movement is part of the job.

Buffalo board lasts longer than standard plywood in tough conditions. The surface takes wear, knocks and regular traffic without breaking down. It keeps working without needing extra coatings or frequent replacement. Moisture is less of a problem too. Buffalo board copes better with damp environments, changing weather and dirty work areas. That is why it is often used in transport, outdoor and utility settings. It is also straightforward to work with. The sheets cut and fix like plywood and fit standard layouts. Once installed, there is very little to look after. Buffalo board is not about looks. It is about grip, strength and doing the job day after day.

Buffalo board is a recognised brand within the phenolic plywood range. Other phenolic plywood boards are also available, sometimes produced with different core materials such as eucalyptus or mixed hardwood, depending on the manufacturer.

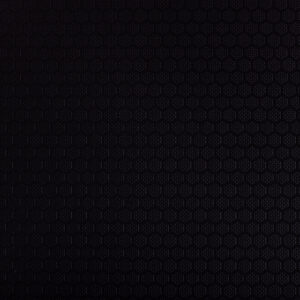

Buffalo board is available in thicknesses from 6.5mm up to 27mm, making it suitable for light walkways as well as heavy-duty floors. Sheets come in common formats including 2440 × 1220mm (8’ x 4’), 2500 × 1220mm (8.2’ x 4’), 2500 × 1250mm (8.2’ x 4.1’) and 3050 × 1525mm (10’ x 5’). Colour options include black, brown and dark brown. Boards are produced with square edges and supplied sealed for added durability. Surface finishes include mesh and hexagon patterns. The face is phenolic. The reverse is smooth. The board meets BS EN636 Class 2 and Class 3 standards. It uses EN314-2 Class 3 glue. Formaldehyde emissions are rated E1. Suitable for interior and exterior use. Buffalo board is classed as non-structural and offers moisture resistance for demanding environments. FSC® certification is available where marked.

Why choose our buffalo board?

If you are looking for a buffalo board UK, the difference is not only in the sheet itself, but in how easy it is to buy the right one. At Sheet Materials Wholesale, we focus on making the process clear, fair and practical for both trade and DIY customers.

Our buffalo board is kept in UK stock, so projects do not stall while waiting for supply. Pricing is set with trade work in mind. We offer good value, with trade discounts, bulk and volume pricing, and pallet deals available when you are ordering more than a few sheets. No inflated list prices. Just a fair cost for a board that is made to work hard.

Delivery is handled with real timelines in mind. Many customers look for a buffalo board near me because they need it fast. We supply across the UK with fast nationwide delivery, including next-day delivery available on selected products. Orders can go straight to the site or to a home address, and every order includes order tracking and a VAT invoice provided as standard.

As one of the established buffalo board suppliers, Sheet Materials Wholesale works with both trade and DIY customers. We keep the process simple. Clear stock levels, fast quotes, and support when you need it. No over-selling. Just the right board, at the right price, delivered when you need it.

FAQ

Where to buy buffalo board?

You can buy buffalo branded phenolic board online from Sheet Materials Wholesale, with delivery across the UK. Buffalo board is supplied from UK stock, with next-day delivery available on selected products and delivery direct to the site or home.

Can you paint buffalo board?

Yes, the buffalo board can be painted, but surface preparation matters. The phenolic face should be lightly sanded and primed first. Paint will adhere better once the surface is keyed properly. This is usually done for marking or specific site requirements, not decorative finishes.

How to cut buffalo board?

Buffalo board cuts like plywood, but the surface is tougher. Use sharp blades and support the sheet well. A circular saw or table saw gives the cleanest result. Always seal exposed edges after cutting to maintain performance.

Can buffalo board get wet?

Buffalo board is designed to handle damp and wet conditions. The phenolic surface and bonding make it suitable for exterior use and transport flooring. It should not be left standing in water long-term, but rain, moisture and site conditions are not an issue when properly sealed in line with installation guidance.

How much is buffalo board?

Buffalo board prices start from around £28 per sheet, depending on thickness, size and specification. For current pricing, availability and bulk options, check the product listings online or request a fast quote.

Showing 1–32 of 34 results

-

6.5mm Eucalyptus Core Dark Brown Hexagon Pattern Anti Slip Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

6.5mm Anti-Slip Hexagon Pattern Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. 6.5mm Hexa phenolic mesh plywood sheets have been manufactured to high standards, making them resistant to corrosion and moisture. Edges of this board are sealed.

£30.88£37.06 Ex VATInc VAT Add to cart -

9mm Eucalyptus Core Black Hexagon Pattern Anti Slip Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

9mm Anti-Slip Hexagon Pattern Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. 9mm Hexa phenolic mesh plywood sheets have been manufactured to high standards, making them resistant to corrosion and moisture. Edges of this board are sealed.

£35.21£42.25 Ex VATInc VAT Add to cart -

9mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2440mm X 1220mm (8′ X 4′)

9mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£80.45£96.54 Ex VATInc VAT Add to cart -

9mm Eucalyptus Core Anti Slip Mesh Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) Pack of 100

9mm phenolic Duroform Mesh Plus board is a great alternative to traditional birch buffalo boards. Pressed on both surfaces with a multi-laminated core and Aica, also known as Dynea, overlay, you can expect a high performance from this board.

£3,132.90£3,759.48 Ex VATInc VAT£31.33£37.60 Per Sheet Add to cart -

9mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 3050mm X 1525mm (10′ X 5′)

9mm 10×5 phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£156.68£188.02 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

37-74 75+ £26.79£32.15 £25.40£30.48 There are 3 more images12mm Eucalyptus/Poplar Core Anti Slip Mesh Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

Anti-Slip Mesh Eucalyptus and Poplar Core mix Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. These sheets have been manufactured to high standards, making them resistant to corrosion and moisture after sealing the edges and back of the board.

£27.91£33.49 Ex VATInc VAT Add to cart -

12mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2440mm X 1220mm (8′ X 4′)

12mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£95.21£114.25 Ex VATInc VAT Add to cart -

12mm Eucalyptus Core Anti Slip Mesh Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) Pack of 75

12mm phenolic Duroform Mesh+ board is a great alternative to traditional birch buffalo boards. Pressed on both surfaces with a multi-laminated core and Aica, also known as Dynea, overlay, you can expect a high performance from this board.

£3,263.88£3,916.66 Ex VATInc VAT£32.64£39.17 Per Sheet Add to cart -

Buy in Bulk & Save

37-74 75+ £47.48£56.98 £44.06£52.87 There are 1 more images12mm Eucalyptus Core Black Hexagon Pattern Anti Slip Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

12mm Anti-Slip Hexagon Pattern Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. 12mm Hexa phenolic mesh plywood sheets have been manufactured to high standards, making them resistant to corrosion and moisture. Edges of this board are sealed.

£48.95£58.74 Ex VATInc VAT Add to cart -

12mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 3050mm X 1525mm (10′ X 5′)

12mm 10×5 phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£171.97£206.36 Ex VATInc VAT Add to cart -

15mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2440mm X 1220mm (8′ X 4′)

15mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£96.20£115.44 Ex VATInc VAT Add to cart -

18mm Birch Core Anti Slip Mesh Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) Pack of 35

18mm phenolic resin impregnated film is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£3,061.07£3,673.28 Ex VATInc VAT£87.46£104.95 Per Sheet Add to cart -

18mm Eucalyptus Core Anti Slip Mesh Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

Anti-Slip Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side 260g/m2 and a smooth film face finish on the other side 130g/m2. These sheets have been manufactured to high standards, making them resistant to corrosion and moisture after sealing the edges and back of the board.

£49.91£59.89 Ex VATInc VAT Add to cart -

18mm Eucalyptus/Poplar Core Brown Mesh Anti Slip Phenolic Faced Film Plywood 2440mm x 1220mm (8′ X 4′) FSC®

Brown Mesh Phenol Faced Eucalyptus/Poplar Core Plywood is designed and manufactured especially for internal applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. These sheets have been manufactured to high standards, making them resistant to corrosion and moisture after sealing the edges and back of the board.

£36.98£44.38 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

25-49 50+ £64.79£77.75 £62.96£75.55 There are 1 more images18mm Eucalyptus Core Dark Brown Hexagon Pattern Anti Slip Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

18mm Anti-Slip Hexagon Pattern Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. 18mm Hexa phenolic mesh plywood sheets have been manufactured to high standards, making them resistant to corrosion and moisture. Edges of this board are sealed.

£66.62£79.94 Ex VATInc VAT Add to cart -

18mm Fire Retardant Faced Birch Core Anti Slip Mesh Phenolic Film Plywood Euroclass B 2440mm X 1220mm (8′ X 4′) Pack of 35

18mm fire retardant phenolic resin impregnated film is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£4,388.21£5,265.85 Ex VATInc VAT£125.38£150.46 Per Sheet Add to cart -

18mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2440mm X 1220mm (8′ X 4′)

18mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£100.33£120.40 Ex VATInc VAT Add to cart -

18mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 3050mm X 1525mm (10′ X 5′)

18mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

Original price was: £204.52 Ex VAT (£245.42 Inc VAT).£193.67£232.40Current price is: £193.67 Ex VAT (£232.40 Inc VAT). Ex VATInc VAT Add to cart -

18mm Eucalyptus Core Anti Slip Mesh Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) Pack of 50

18mm phenolic Duroform Mesh+ board is a great alternative to traditional birch buffalo boards. Pressed on both surfaces with a multi-laminated core and Aica, also known as Dynea, overlay, you can expect a high performance from this board.

£2,854.42£3,425.30 Ex VATInc VAT£57.09£68.51 Per Sheet Add to cart -

18mm Eucalyptus Core Black Hexagon Pattern Anti Slip Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

18mm Anti-Slip Chinese Hexagon Pattern Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. 18mm Chinese Hexa phenolic mesh plywood sheets have been manufactured to high standards, making them resistant to corrosion and moisture. Edges of this board are sealed.

Original price was: £54.65 Ex VAT (£65.58 Inc VAT).£49.95£59.94Current price is: £49.95 Ex VAT (£59.94 Inc VAT). Ex VATInc VAT Add to cart -

18mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2500mm x 1220mm (8.2′ x 4′)

18mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£104.07£124.88 Ex VATInc VAT Add to cart -

18mm Birch Core Dark Brown Anti Slip Hexagon Phenolic Faced Film Buffalo Plywood 2440mm X 1220mm (8′ X 4′)

18mm phenolic resin impregnated film Buffalo Riga Heksa board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured hexagon pattern is pressed onto the other.

£122.63£147.16 Ex VATInc VAT Add to cart -

21mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2500mm x 1220mm (8.2′ x 4′)

21mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

Original price was: £126.47 Ex VAT (£151.76 Inc VAT).£112.00£134.40Current price is: £112.00 Ex VAT (£134.40 Inc VAT). Ex VATInc VAT Add to cart -

24mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2500mm x 1220mm (8.2′ x 4′)

24mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£146.75£176.10 Ex VATInc VAT Add to cart -

27mm Birch Core Anti Slip Mesh Phenolic Faced Film Buffalo Plywood 2500mm x 1220mm (8.2′ x 4′)

27mm phenolic resin impregnated film Buffalo board is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

£184.58£221.50 Ex VATInc VAT Add to cart -

12mm Faced Birch Core Anti Slip Mesh Phenolic Film Plywood 2440mm X 1220mm (8′ X 4′)

12mm phenolic resin impregnated film is pressed on both surfaces of the board under high pressure and temperature, smooth on one surface and a textured pattern is pressed onto the other.

POA Get a quote -

12mm Eucalyptus Core Anti Slip Mesh Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

Anti-Slip Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. These sheets have been manufactured to high standards, making them resistant to corrosion and moisture after sealing the edges and back of the board.

POA Get a quote -

12mm Black Hexagon Pattern Eucalyptus Core Slip Resistant Phenolic Film Plywood 2440mm X 1220mm (8′ X 4′) Pack of 75

12mm Black Hexagon Pattern Eucalyptus Core Slip Resistant Phenolic Film Plywood 2440mm X 1220mm (8′ X 4′) These buffalo boards come in packs of 75 sheets.

POA Get a quote -

12mm Brown Mesh Phenol Faced Poplar Core Plywood 2440mm x 1220mm (8′ X 4′)

Brown Mesh Phenol Faced Poplar Core Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. These sheets have been manufactured to high standards, making them resistant to corrosion and moisture after sealing the edges and back of the board.

POA Get a quote -

12mm Eucalyptus Core Dark Brown Hexagon Pattern Anti Slip Phenolic Faced Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

12mm Anti-Slip Hexagon Pattern Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. 12mm Hexa phenolic mesh plywood sheets have been manufactured to high standards, making them resistant to corrosion and moisture. Edges of this board are sealed.

POA Get a quote -

12mm Eucalyptus Core Anti Slip Mesh Phenolic Film Plywood 2440mm X 1220mm (8′ X 4′) FSC®

Anti-Slip Mesh Eucalyptus Core Phenolic Resin Hardwood Plywood is designed and manufactured especially for internal & external applications, has an anti-slip mesh pattern on one side and a smooth film face finish on the other side. These sheets have been manufactured to high standards, making them resistant to corrosion and moisture after sealing the edges and back of the board.

POA Get a quote -

18mm Black Hexagon Pattern Eucalyptus Core Slip Resistant Phenolic Film Plywood 2440mm X 1220mm (8′ X 4′) Pack of 50

18mm Black Hexagon Pattern Eucalyptus Core Slip Resistant Phenolic Film Plywood 2440mm X 1220mm (8′ X 4′). These buffalo boards come in packs of 50 sheets.

POA Get a quote