Chipboard

Chipboard, also called low-density fibreboard or particleboard, is a thick fibre ‘paper’, naturally made from recycled small timber strips mixed with resin.

Chipboard resembles cardboard in various ways. Typically, it is a type of non-corrugated cardboard, implying that it lacks corrugated fluting between the two layers, which creates the hollow in corrugated cardboard.

What is Chipboard?

To get a better understanding of what chipboard is, it is worth breaking down how the panels are made.

- The chipping process: This process produces chipboard wood strips with uniform sizes that are then dried. Drying ensures that the chips maintain the right moisture content. Then, the chips are screened to sort them into different sizes.

- The glueing process: This is when the chipboard comes together. The process uses a resin treatment, which glues the wood chips together.

- Pressing: At this step, the chipboard is pressed under high temperature and left to cool. The final product after the cooling process has a solid bond.

After cooling, the board is trimmed and sanded to size and smoothness. Some of them are laminated, melamine-faced, or veneered to improve appearance and make them easy to use.

What is Chipboard Used For?

Chipboard has a wide range of uses. The most common applications are making a secure base layer for flooring (e.g., laminate, vinyl, solid wood, or engineered timber).

Chipboard is also used for creating cost-efficient flooring – mostly in areas where aesthetics is not that crucial, such as a loft space used for storage.

Here are some other uses of chipboard sheets:

- Kitchen cabinets

- Kitchen worktops

- Flatpack furniture

- Home accents for interiors (e.g., mouldings and trims around doors and windows)

- Furniture elements (e.g., wardrobe backs, drawer bottoms)

- Packaging

- Soundproofing and absorption (e.g., music venue flooring and walls)

Types of Chipboard

Here are the main types of chipboard you can find on Sheet Materials Wholesale, to fit all your specialised projects:

Underfloor Heating Chipboard

These pre-routed or machined chipboards come with grooves to accommodate underfloor heating pipework. The routing helps distribute heat evenly and allows the pipes to sit flush and keep the floor even.

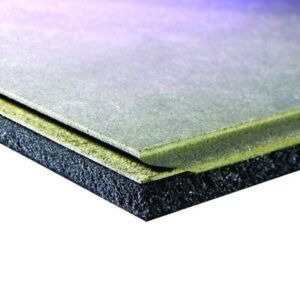

Acoustic Flooring

Based on overlay or deck boards, these chipboards are designed to reduce sound transference. They often have special layers and, at times, cement-based tops to help deaden sound in flats, multi-storey buildings, upstairs rooms, or where building regulations demand it.

Melamine-Faced Chipboard

These are chipboards with resin-impregnated melamine facing (one or both sides). They come ready to use and decorate without further finishing and are utilised in furniture, shelving, kitchens, cabinets, etc.

8×4 Chipboard

This is the most common standard sheet size used for general sheeting work, including joinery, partitioning, shelves, furniture, etc. Buying the standard size offers value, reduces waste, and is easier to work with.

Fire-Retardant Chipboard

Fire-retardant options are treated to resist igniting or slow fire spread. Our options combine fire performance with Euroclass B and a P5 moisture rating to protect your walls and help your builds be safe and up to code.

Moisture-Resistant Chipboard

‘Moisture resistant’ chipboards are designed to withstand humidity and moisture better than a standard board. They are often graded on the P-scale for moisture resistance (especially P5) and find applications in floors, lofts, kitchens, and other minimally exposed settings.

Grades

- P1 – Used for general purposes such as joinery and basic building work.

- P2 – Not load-bearing and can be used in the construction of cabinets.

- P3 – Not load-bearing and is moisture resistant.

- P4 – It is load-bearing only for dry conditions.

- P5 – It is moisture-resistant and load-bearing. It is preferred for chipboard floorboards.

- P6 – It is load-bearing and heavy-duty for dry conditions.

- P7 – It is moisture-resistant, load-bearing, and heavy-duty.

P2 Chipboard

P2 chipboard is ideal for interior furniture and fixtures in dry conditions, and moisture exposure is limited. It has a smooth surface, excellent for veneering or laminating to add decorative appeal to furniture.

P5 Chipboard

P5 is a flooring-grade chipboard that is appropriate for load-bearing uses where there is fluctuating moisture because of extreme humidity. P5 chipboard is typically used for flooring.

P6 Chipboard

P6 is high-density chipboard with a well-sanded exterior. It is also perfect for laminating or coating for dry conditions. It is commonly used in making load-bearing walls, floors, and roofs.

Chipboard Edging Tape Products

To keep your chipboards performing at a high level, we stock edging materials that are often glued and ironed on to cover the raw edges of a panel.

We also have veneer and wood-look edging strips that come in at 22mm wide x 50m long and about 0.5 to 0.6mm in thickness.

Benefits

Here are the key benefits of using chipboard boards:

- They are uncomplicated and therefore effortless to use.

- Cutting chipboard is easy. You can trim the sheet to fit in awkward areas like cupboards and stairs.

- Chipboards are affordable.

- It is easy to use nails, screws, and adhesives with them.

- All sides are perfectly grooved, which allows every piece to interlock securely, creating a reliable connection. Adding glue will add strength to the connection and prevent the chipboard flooring from squeaking.

Chipboard quality will vary depending on where you buy it. Sheet Materials Wholesale offers top-notch quality products at a pocket-friendly price.

FAQs

What are the main uses of chipboard?

Chipboard is used for a wide range of applications, including furniture, flooring, insulation, packing materials, and arts and crafts.

How is MDF different from chipboard?

Chipboard is a lower-cost type of wood made from larger wood chips and resin, with a rough surface and low density. MDF, on the other hand, is high-quality, made from finer wood fibres and resin, and offers a smooth surface that takes paint well.

How long can chipboard last?

That depends on the type, but with great care, you can use chipboard for more than a decade or two. Reinforce it with the proper protections and ensure it is properly installed for the best performance.

Showing 1–32 of 62 results

-

Egger D4 Chipboard Adhesive 1L Bottle

EGGER D4 Adhesive is used for bonding the board to the joist and within the tongue and groove joint as well as for sealing nail heads and adjacent areas. 1 bottle of D4 Glue will cover 3 sheets if used on the sheet and joists. If not used on joists, it will cover 5.5 sheets.

£13.83£16.60 Ex VATInc VAT Add to cart -

CaberFix D4 Chipboard Adhesive 1L Bottle

CaberFix D4 Adhesive is used for bonding the board to the joist and within the tongue and groove joint as well as for sealing nail heads and adjacent areas. 1 bottle of D4 Glue will cover 3 sheets if used on the sheet and joists. If not used on joists, it will cover 5.5 sheets.

£13.66£16.39 Ex VATInc VAT Add to cart -

JCW Perimeter Edging Strip (75mm x 5mm x 50m)

5mm thick foam strip to isolate acoustic flooring from perimeter walls and maintain the acoustic integrity of the structure. For use with Acoustic Battens, Acoustic Cradles and Acoustic Decks.

£23.21£27.85 Ex VATInc VAT Add to cart -

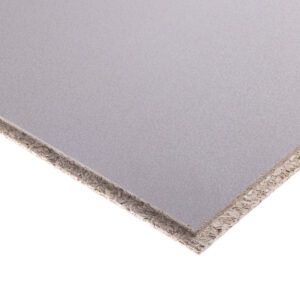

12mm P2 Furniture Grade Chipboard 2440mm x 1220mm (8′ x 4′) FSC® Pack of 72

12mm Furniture Grade Chipboard is a highly versatile and strong board used in making furniture as well as kitchen elements.

£722.54£867.05 Ex VATInc VAT£10.04£12.05 Per Sheet Add to cart -

15mm White Melamine Faced Chipboard Double-sided Shelving 2440mm x 1220mm (8′ x 4′) FSC®

15mm Non-textured smooth white chipboard in white provides extreme support for items around the home.

£31.19£37.43 Ex VATInc VAT Add to cart -

15mm P2 Furniture Grade Chipboard 2440mm x 1220mm (8′ x 4′) FSC® Pack of 58

15mm Furniture Grade Chipboard is a highly versatile and strong board used in making furniture as well as kitchen elements.

£698.97£838.76 Ex VATInc VAT£12.05£14.46 Per Sheet Add to cart -

18mm P2 Furniture Grade Chipboard 2440mm x 1220mm (8′ x 4′) FSC®

18mm Furniture Grade Chipboard is a highly versatile and strong board used in making furniture as well as kitchen elements.

Original price was: £17.80 Ex VAT (£21.36 Inc VAT).£16.55£19.86Current price is: £16.55 Ex VAT (£19.86 Inc VAT). Ex VATInc VAT Add to cart -

18mm White Melamine Faced Chipboard Double-sided Shelving 2440mm x 1220mm (8′ x 4′) FSC®

18mm Non-textured smooth white chipboard in white provides extreme support for items around the home.

£34.85£41.82 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

40-79 80+ £8.53£10.24 £8.35£10.02 There are 1 more images18mm Egger P5 Tongue and Groove Moisture Resistant Chipboard Flooring TG4E 2400mm x 600mm (8′ x 2′) FSC®

18mm Egger P5 tongue and groove chipboard is a moisture-resistant structural grade flooring board. It is generally used in flooring applications as the board’s construction adds strength when panels are slotted together and screwed or nailed down to floor joists.

£8.79£10.55 Ex VATInc VAT Add to cart -

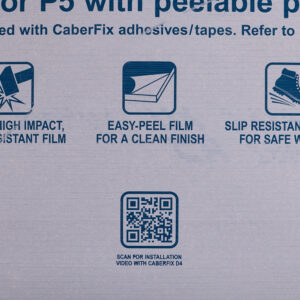

18mm Egger Peel Clean Xtra P5 Tongue and Groove Moisture Resistant Chipboard Flooring TG4E 2400mm x 600mm (8′ x 2′) FSC®

18mm Tongue and Groove Chipboard, commonly known as P5 is a structural grade flooring board highly regarded by builders because of its moisture-resistant properties. 18mm T&G flooring chipboard is typically utilised in flooring applications.

£13.45£16.14 Ex VATInc VAT Add to cart -

18mm Caberfloor P5 Tongue And Groove Moisture Resistant Chipboard Flooring TG4E 2400mm x 600mm (8′ x 2′) FSC®

18mm Caberfloor P5 tongue and groove chipboard is a moisture-resistant structural grade flooring board. It is generally used in flooring applications as the board’s construction adds strength when panels are slotted together and screwed or nailed down to floor joists. Generally used on joists with 400mm centres.

£8.44£10.13 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

50-99 100+ £12.18£14.62 £11.80£14.16 There are 1 more images18mm CaberDek P5 Tongue and Groove Moisture Resistant Chipboard Flooring TG4 2400mm x 600mm (8′ x 2′) FSC®

18mm Tongue and Groove Chipboard, commonly known as P5 is a structural grade flooring board highly regarded by builders because of its moisture-resistant properties. 18mm T&G flooring chipboard is typically utilised in flooring applications. Caberdek provides weather exposure of up to 60 days. Generally used on joists with 400mm centres.

£12.69£15.23 Ex VATInc VAT Add to cart -

18mm JCW Cement Particle Board 1200mm x 600mm (4′ x 2′)

The JCW 18mm Cement Particle Board is a high-density acoustic panel for floors and ceilings, reducing noise while meeting fire safety standards. Comes with a tongue-and-groove design for easy installation, it ensures superior soundproofing and durability. The 18mm board offers a 30-minute fire rating, making it ideal for homes and commercial spaces.

£37.41£44.89 Ex VATInc VAT Add to cart -

18mm P2 Furniture Grade Chipboard 2440mm x 1220mm (8′ x 4′) FSC® Pack of 49

18mm Furniture Grade Chipboard is a highly versatile and strong board used in making furniture as well as kitchen elements.

£730.10£876.12 Ex VATInc VAT£14.90£17.88 Per Sheet Add to cart -

Buy in Bulk & Save

22-44 45+ £14.36£17.23 £13.76£16.51 There are 3 more images18mm P4 Chipboard Loft Panels TG2 LE 1220mm x 320mm (4′ x 1) FSC® Pack of 3

18mm P4 Chipboard Loft Panels is designed to be compact in size which means that they are easy to move by hands due to light weight. They can easily fit in loft and tight spaces. With the 18mm Chipboard P4 Loft panel, you will find a seamless installation process and perfect fit for the job as it has a (T&G) tongue and groove section along longer sides of the panel.

£15.12£18.14 Ex VATInc VAT£5.04£6.05 Per Sheet Add to cart -

19mm JCW Acoustic Deck for Timber Floor Insulation MDF 1200mm x 600mm (4′ x 2′)

MDF based acoustic deck overlay boards for timber floors with good airborne and excellent impact performance.

£16.68£20.02 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

32-63 64+ £9.73£11.68 £9.43£11.32 There are 1 more images22mm Egger P5 Tongue and Groove Moisture Resistant Chipboard Flooring TG4E 2400mm x 600mm (8′ x 2′) FSC®

22mm Egger P5 tongue and groove chipboard is a moisture-resistant structural grade flooring board. It is generally used in flooring applications as the construction of the board adds strength when boards are slotted together and screwed or nailed down to floor joists.

£10.03£12.04 Ex VATInc VAT Add to cart -

22mm Egger Peel Clean Xtra P5 Tongue and Groove Moisture Resistant Chipboard Flooring TG4E 2400mm x 600mm (8′ x 2′) FSC®

22mm Tongue and Groove Chipboard, commonly known as P5 is a structural grade flooring board highly regarded by builders because of its moisture-resistant properties. 22mm T&G flooring chipboard is typically utilised in flooring applications.

£16.25£19.50 Ex VATInc VAT Add to cart -

22mm Egger Protect P5 Tongue and Groove Moisture Resistant Chipboard Flooring TG4E 2400mm x 600mm (8′ x 2′) FSC®

22mm Tongue and Groove Chipboard, commonly known as P5, is a structural grade flooring board highly regarded by builders because of its moisture-resistant properties. 22mm T&G flooring chipboard is typically utilised in flooring applications.

£19.68£23.62 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

10-19 20+ £7.65£9.18 £7.10£8.52 There are 1 more images22mm Smooth White Melamine Pre-Glued Edging Tape Strip 50m

Also known as veneer edge banding or wood veneer edging tape, each professionally made roll is fleeced with non-woven fabric and sanded for a perfectly smooth surface.

£7.89£9.47 Ex VATInc VAT Add to cart -

22mm Caberfloor P5 Tongue And Groove Moisture Resistant Chipboard Flooring TG4E 2400mm x 600mm (8′ x 2′) FSC®

22mm Caberfloor P5 tongue and groove chipboard is a moisture-resistant structural grade flooring board. It is generally used in flooring applications as the construction of the board adds strength when boards are slotted together and screwed or nailed down to floor joists. Generally used on joists with 600mm centres.

£9.59£11.51 Ex VATInc VAT Add to cart -

22mm UFH Unfoiled Pre-Routed Underfloor Heating P5 Flooring Grade Chipboard For 12mm Pipe 2400mm x 600mm FSC®

The 22mm underfloor heating p5 moisture resistant chipboard is a durable, unfoiled board commonly used in a range of flooring applications. Across the market, it is well known as 22mm UFH chipboard. Channels are routed to suit a 12mm pipe, and are machined at 150mm centres with returns.

£30.33£36.40 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

10-19 20+ £11.15£13.38 £10.34£12.41 There are 1 more images22mm Textured White Melamine Pre-Glued Edging Tape Strip 50m

Also known as veneer edge banding or wood veneer edging tape, each professionally made roll is fleeced with non-woven fabric and sanded for a textured surface.

£11.49£13.79 Ex VATInc VAT Add to cart -

Buy in Bulk & Save

41-81 82+ £14.69£17.63 £14.22£17.06 There are 1 more images22mm CaberDek P5 Tongue and Groove Moisture Resistant Chipboard Flooring TG4 2400mm x 600mm (8′ x 2′) FSC®

22mm Tongue and Groove Chipboard, commonly known as P5 is a structural grade flooring board highly regarded by builders because of its moisture-resistant properties. 22mm T&G flooring chipboard is typically utilised in flooring applications. Caberdek provides weather exposure of up to 60 days. Generally used on joists with 600mm centres.

£15.46£18.55 Ex VATInc VAT Add to cart -

22mm UFH Foiled Pre-Routed Underfloor Heating P5 Flooring Grade Chipboard For 12mm Pipe 2400mm x 600mm FSC®

The 22mm underfloor heating p5 moisture resistant chipboard is a durable, foiled board commonly used in a range of flooring applications. Across the market, it is well known as 22mm UFH chipboard. Channels are routed to suit a 12mm pipe, and are machined at 150mm centres with returns.

£33.71£40.45 Ex VATInc VAT Add to cart -

22mm HydroFlam P5 Tongue And Groove Fire Retardant Chipboard Flooring Euroclass B 2400mm x 600mm (8′ x 2′) FSC® Pack of 80

22mm Fire-rated P5 Chipboard. This is a universal HydroFlam Euroclass B-rated and Moisture P5 rated Chipboard used in humid conditions, which allows it to reach certain certifications required for building regulations. Its main uses are Flooring and Walls.

£2,643.20£3,171.84 Ex VATInc VAT£33.04£39.65 Per Sheet Add to cart -

22mm UFH Unfoiled Pre-Routed Underfloor Heating P5 Flooring Grade Chipboard For 16mm Pipe 2400mm x 600mm FSC®

The 22mm underfloor heating p5 moisture resistant chipboard is a durable, unfoiled board commonly used in a range of flooring applications. Across the market, it is well known as 22mm UFH chipboard. Channels are routed to suit a 16mm pipe, and are machined at 150mm centres with returns.

£30.94£37.13 Ex VATInc VAT Add to cart -

22mm UFH Foiled Pre-Routed Underfloor Heating P5 Flooring Grade Chipboard For 16mm Pipe 2400mm x 600mm FSC®

The 22mm underfloor heating p5 moisture resistant chipboard is a durable, foiled board commonly used in a range of flooring applications. Across the market, it is well known as 22mm UFH chipboard. Channels are routed to suit a 16mm pipe, and are machined at 150mm centres with returns.

£34.77£41.72 Ex VATInc VAT Add to cart -

22mm JCW Cement Particle Board 1200mm x 600mm (4′ x 2′)

The JCW 22mm Cement Particle Board is a high-density acoustic panel for floors and ceilings, reducing noise while meeting fire safety standards. Comes with a tongue-and-groove design for easy installation, it ensures superior soundproofing and durability. The 22mm board offers a 30-minute fire rating, making it ideal for homes and commercial spaces.

£44.18£53.02 Ex VATInc VAT Add to cart -

28mm JCW Acoustic Deck for Timber Floor Insulation Chipboard 2400mm x 600mm (8′ x 2′)

28mm Chipboard-based T&G acoustic deck overlay boards made of resilient layer and chipboard with good airborne and excellent impact performance. Commonly used in timber and concrete subfloors.

£30.60£36.72 Ex VATInc VAT Add to cart -

28mm JCW Acoustic 28 Plus Cement Particle Board 1200mm x 600mm (4′ x 2′)

SoundBoard 28 Plus is a 28mm acoustic overlay board with cement particle board and a resilient layer, reducing impact and airborne noise. (10mm acoustic overlay & 18mm cement particle board) Ideal for refurbishments, new builds, and underfloor heating systems.

£33.56£40.27 Ex VATInc VAT Add to cart -

30mm JCW Acoustic Deck 30C for Timber Floor Chipboard 2400mm x 600mm (8′ x 2′)

Acoustic deck 30C is a chipboard based premium acoustic deck overlay or direct to joist board for timber floors with excellent airborne and good impact performance.

£33.81£40.57 Ex VATInc VAT Add to cart